Biomass boilers

AND ALL EQUIPMENTS FOR THEM, TRANSPORT FUELS SYSTEMS

|

|

|

Deliveries of these technologies we prepare with the manufacturer with 20 – years tradition and more of than 400 realized installations in Europe.

Additional charge for controlling of boiler via PLC SIEMENS CLIMATIX with touch panel with remote control via internet

Highly effective power modulation on the basis of load of boiler and heating demands

Processed types of biomass: wood chips, sawdust, shavings, wood pellets, agri pellets

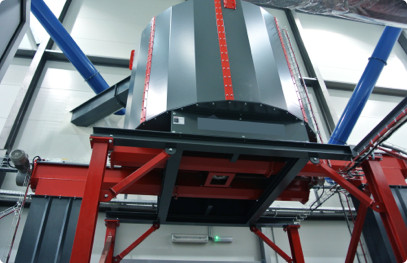

Automatic industrial HOT WATER boiler – 100 kW – 6 000 kW

Purpose of use :

Production of hot water to 105oC for central heating of buildings, drying timber and pallets in hot water dryers, heating of industrial halls and commercial real estate

|

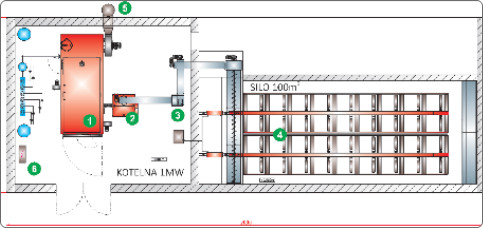

An example of arrangement of automatic boiler room with an output

1 – 1 MW hot water boiler |

|

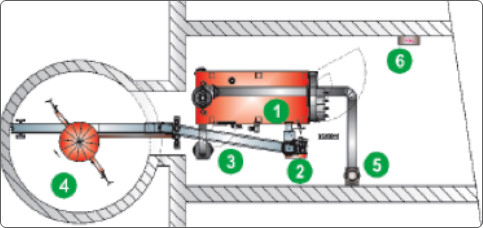

An example of arrangement of automatic boiler room with an output

300 kW – the fuel storage tank with a rotating levying for about

100 hours of operation

1 – 300 kW hot water boiler

2 – fuel shaft with fire separation

3 – Screw path transport fuel

4 – rotational removing system

5 – combustion gases path, chimney

6 – electric switchboard, measurement and regulation

Automatic industrial HOT AIR boiler – 150 kW – 6 000 kW

Purpose of use:

Installation in technological sets for making the drying media into the drying technology, which can be used the combustion gases in combination with the air like pellet production.

Variable embodiment according to the type of fuel used.

|

|

|

|

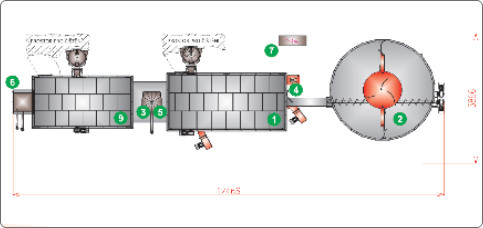

An example of arrangement of automatic boiler room

with an output 1 MW – for drum dryer

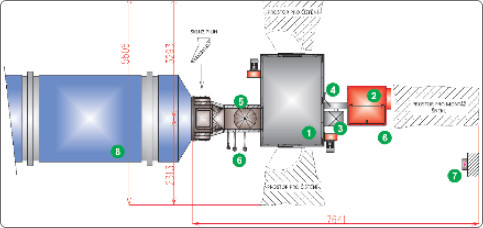

An example of arrangement of automatic boiler room with an output

1,8 MW with fuel tank 10 m3 including post-combustion

chamber for extending flue-gas

1 – hot air boiler

2 – production in front tank of the fuel

3 – technological suction of air

4 – extinguishing equipment

5 – emergency caliduct

6 – connection with tight flaps

7 – Measurement and control of the boiler

8 – dryer

9 – extension chamber

SYSTEMS FOR TRANSPORT OF FUELS

– transport of the wooden chips and sawdust from the silo or storage bunkers to the boiler – are used drivers by LENZE (Germany)

|

|

|

|

|

|

Chimney systems – products are used by company M E T A L O T E R M ( Netherlands )

Intelligent measurement and control – S I E M E N S

The whole course of combustion from the fuel from the tank to the connection to the chimney flue pipe is regulated and controlled by the microprocessor equipment with a memory developed by the SIEMENS.

|

|

|